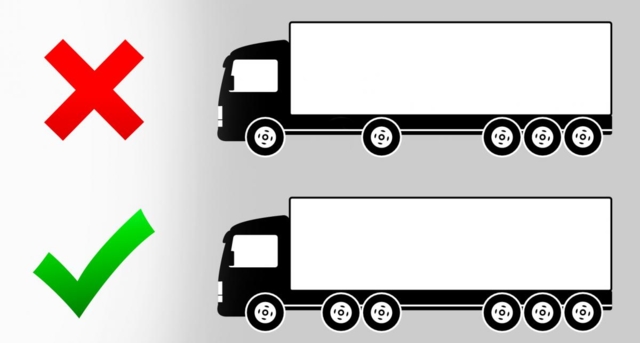

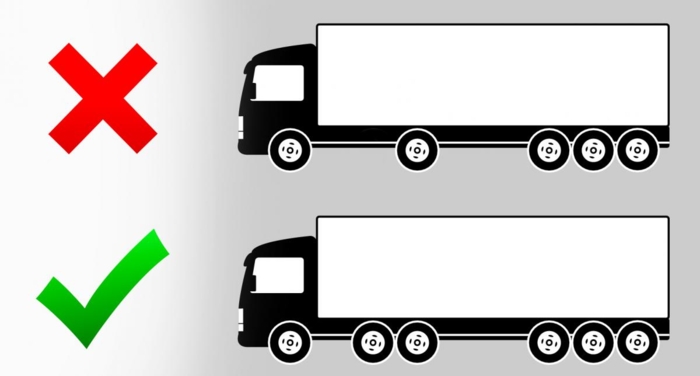

Two-axled trucks not recommended in Norway

A lot of two-axled trucks get stuck on snowy Norwegian roads. There is a simple explanation for this.

Foreign semi-trailer trucks are infamous among road rescue service personnel. They get stuck a lot more often than their Norwegian counterparts, often causing hold-ups and chaos that affects thousands of fellow drivers. Some blame this on ill-suited tires and/or poor driver judgement. But the story might not be quite that simple.

Three-axled vehicles not that common throughout Europe

You rarely get to see a two-axled semi-trailer truck with Norwegian registration plates. The reason for this is experience. Most hauliers choose three-axled vehicles because this solution has been proven to work very well, even in harsh winter conditions. By having an additional liftable axle you have the option of adding more weight and thus increasing friction on the driving axle. We also see more and more truck owners investing in three-axled trucks with tandem drive, a solution where both rear axles drive the vehicle. Common for both solutions is a significant increase in all-year drivability when compared to two-axled trucks.

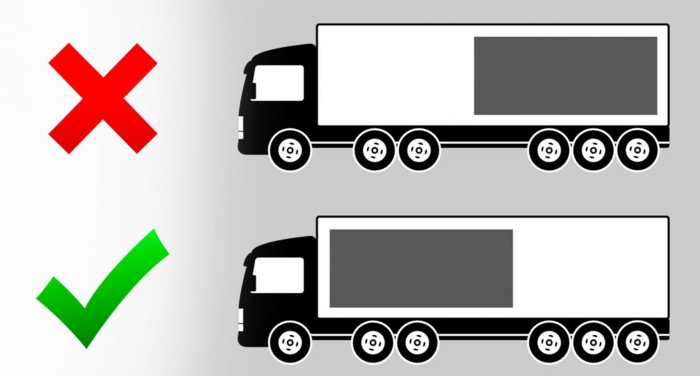

Placement of cargo also a contributing factor

The number of axles is one thing. But the advantage of having three axles might be lost if you don't properly consider how the cargo is distributed within the trailer. In order to maintain maximum pressure on the driving axles, one should place the cargo forward inside the trailer. This way the centre of gravity will work in the drivers advantage, and not just act as dead weight behind the trailer truck.

This might seem like basic knowledge to most truck drivers, but Norway still sees a considerable amount of continental trucks getting stuck because of these factors.

To sum it up: If you intend to transport goods by semi-trailer truck safely in Norway, you're best off with a tree-axled truck and front-based cargo placement.